3 Ways a Ventilated Hy-Grade Steel Roof Improves Your Home

One Key Element to an efficient and long lasting, worry-free roofing system is ventilation.

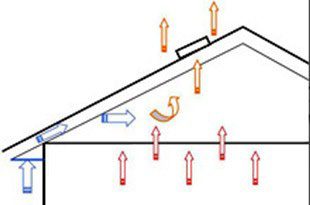

This diagram illustrates the basic roof structure. With a properly ventilated and insulated attic, the temperature in the attic and the temperature outside will be the same, or within a few degrees. The three main reasons that a roof needs to have ventilation are:

- To reduce the temperature in the attic

2. To create a way to expel the trapped heat and moisture in the attic

3. To allow the air to circulate in the attic preventing condensation from forming

When warm air escapes through the ceiling and into the attic, moisture comes with it. If this moisture is allowed to accumulate in the attic, it creates the possibility for mould to form and for wood rot in the structure. In the cooler months, when this warm air contacts the cold roof decking, the moisture can then condense and turn into water inside the roof; causing leaks, rot, and mould.

In a house with a properly sealed vapour barrier and sufficient insulation, the amount of heat escaping into the attic is reduced. By adding soffit (inlet) vents, cooler and drier air from outside is allowed to enter the attic; helping to reduce the temperature inside the attic. By adding dry air into the attic, it also allows the moisture in the air to be dispersed.

CHALLENGE

A major concern with any steel roofing system is condensation. As the warm, moist air escapes through the old roof, this moisture will “cling” to the steel. When you add a cold exterior, with a warm interior, you are now creating a prime opportunity for moisture to accumulate (condense) between the steel roof and the old roof. If enough moisture condenses on the back of the steel, you can then have water between the roofs. In the winter, this water can freeze and create ice between the roofs.

Any steel roofing system requiring a membrane in place of double wood strapping is tacit admission that roofing system creates condensation that would leak back into your attic without the membrane. There are circumstances when membrane AND double wood strapping are appropriate like with new construction and in valleys as added protection.

SOLUTION

With Hy-Grade’s double wood strapping AND dual ventilation system, with in-line shake vents AND venting at the ridge(s), your roof AND attic receive outstanding air exhaust. Couple these with sufficient air intake through soffit or Moore vents, and you’re looking at 30% reduction in your energy bills. The double wood strapping creates Above Sheathing Ventilation (AVS) space by nailing 1×3 wood battens vertically on your shingled roof followed with 2×2 wood battens horizontally into which are nailed the Hy-Grade steel shakes, creating a 5-6 cm air space.

The installation of Hy-Grade’s moulding’s also play a part. Hy-Grade’s “bull nose” starter strips sit on the 1x3s at the eaves of the roof, and is positioned about ½ an inch from the fascia allowing air to enter our system. At the top of our system, the vent at the ridge, the ridge cap sits on top of our shakes, with a support/baffle underneath which allows air to exit the system.

In addition, at the end of each row of shakes, the shakes are cut to fit into our moldings. Any place where a shake is fit into a molding, it is cut back ½ an inch to allow for expansion. This also creates additional areas for air to enter and exit our system.

Contact Hy-Grade Steel Roofing System For Your Free—No Obligation Quote

or

Fill out our online form HERE.