How Much Does a Metal Roof Cost?

Hy-Grade Steel Roofs offer great value for your investment.

There is a wide price range when it comes to residential metal roof cost in Ontario. Influenced by factors such as roof size, slope, design, installation methods, materials, contractor insurance, and additional features like skylights, vents, insulation. Check out our video below to find out how much this Hy-Grade Steel Roof Costs.

Connect With Us – Request Quote

We do in person measurements and quotations to offer the most comprehensive quote possible. Measuring from satellite imagery does not offer the accuracy needed to properly quote the last roof your home will ever need.

Our team is here to assist you with your inquiries. All quotations are free, no-obligation (no pushy sales people). Find out how much a metal roof cost for your home today.

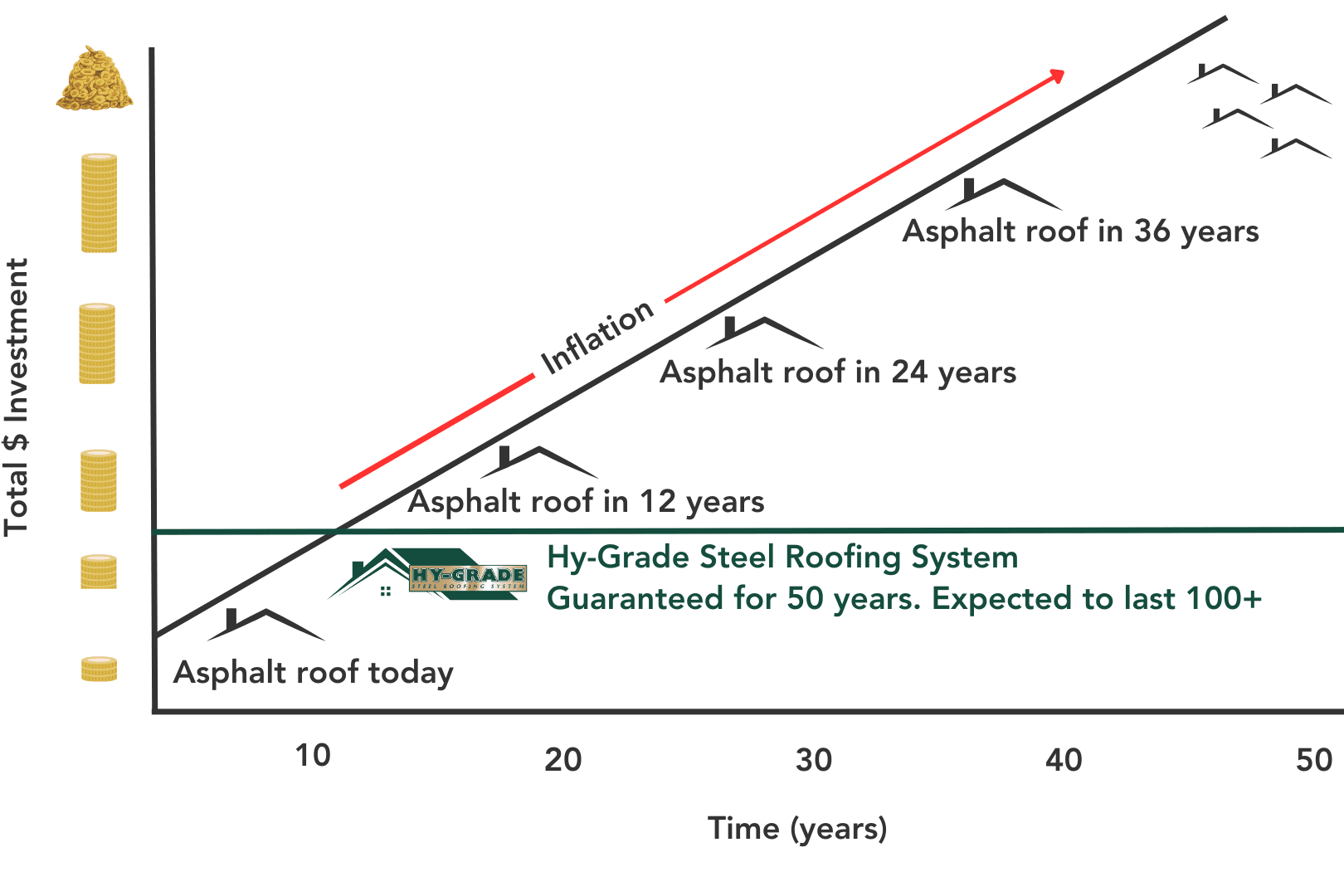

While a Hy-Grade Metal Roof cost more upfront than a standard asphalt roof, it saves you money in the long run.

Why? Asphalt roofs often need repairs or replacements after just 12 years, while Hy-Grade Steel Roofs come with a 50-year warranty and are expected to last well over 100 years.

That’s one steel roof compared to four asphalt roof replacements!

Metal Roof Cost

A Roof That Lasts a Lifetime – Hy-Grade

We’ve been perfecting our steel roofing system since 1988, installing over 18,000+ roofs across Ontario—that’s over 33 million square feet! Backed by our 50-Year No-Leak Warranty, this will be the last roof you ever buy.

We discuss below some factors that influence our steel roofs cost. Not all steel roofs are made the same, learn more below about our roofing system.

High-Quality Materials

26-Gauge Steel with 4-Mil PVC Coating: The toughest coating on the market. It moves with the steel during temperature changes and won’t crack, chip, or peel—even during the manufacturing process or installation. It is the only coating used in metal roofing that can endure a 180 degree bend, and not crack. When the trim pieces go through the manufacturing process and the customization for your roof on site, the coating must be able to withstand a 180 degree bend. The coating on a metal roof is extremely important for the longevity. Learn more about barrier series coatings here.http://www.baycoat.com/resources.html

Engineered for Expansion and Contraction: Steel expands when warm and contracts when cold. Our patented expansion socket lets each panel move naturally without stressing the fasteners. This means no cracks, no leaks—just reliable performance in every season.

Double Roof Strapping: Built to Protect

We install double strapping before laying our steel shakes. This creates an air gap that:

Keeps your home cooler in the summer.

Prevents moisture buildup and protects your roof deck.

Levels out dips or sags, improving curb appeal.

The double strapping also allows every piece of metal to expand and contract freely, so there’s no stress on fasteners and no risk of leaks.

Its What’s Inside That Counts

Underneath the visible shakes, your Hy-Grade roof is packed with trim that has been designed to endure temperature changes and make sure water and snow shed to your eave. Our system may look like some others, but it truly is different. For example, a valley is where two downward sloping roof surfaces meet. The valley therefore collects alot of water, snow and debris (from trees ect). Most competitors will use a pan, and cut the shakes that end at the valley to sit in the pan. If that pan becomes clogged with roof debris the water will overflow onto your roof deck, and potentially end up in your attic. Our Valley system has 7 parts, a basic pan, a bottom valley pan, inner valleys and a cap. They add multiple layers of protection against water reaching your roof deck. Every one of our trim pieces adds layers of protection against leaks. Ask our roofing consultants about the other components.

Expert Installation and Quality Control

Our installers are factory-trained and certified to meet our high standards. Once your roof is installed, our separate quality control team inspects it to ensure it meets every detail of our rigorous guidelines. That’s why we confidently offer a Lifetime Workmanship Warranty in addition to our 50-Year No-Leak Promise.

If you need support later—like adding a vent or removing a chimney—our Service Team is always here to help.

Proudly Local

We manufacture our roofing system in Guelph, supporting local businesses and families across the province.

Our steel comes from Hamilton, Ontario, so you know it’s high-quality and built to last.

A Family Business You Can Trust

Hy-Grade has been family-owned and operated for over 35 years, and we’re here to stay. With a long-term plan in place, you can trust us to honor your warranty for decades to come.

When you choose Hy-Grade, you’re not just buying a roof—you’re investing in permanent peace of mind.

Getting your new Hy-Grade Steel Roof is as easy as 1-2-3.

1

Connect with Us and Request a Quote

One of our team members will be in touch with you to set up a time to come visit you at your property

2

We Measure Your House, in Person!

Our experienced Roofing Consultant will come to your property to measure your roof and give you an accurate quotation.

3

Book your installation with your Roofing Consultant

You don’t even need to leave your home. Our Roofing Consultants can answer any questions you may have and book you in for your installation on the spot!

Financing Available

A Hy-Grade Steel Roofing System is an investment in your home. Just like you might finance an interior home renovation, you can finance the purchase of your roof. Financing is a great way to fit the investment within your budget with low weekly, bi-weekly, or monthly payment options. With financing through one of our leading lenders, you can afford the permanent roofing solution for your #1 investment, and never worry about replacing your roof again!